The modern, collaborative economy leads lots of companies to partner up to produce the best possible products for retail sale. Many manufacturers rely on third parties to help them create precision components by providing metal stamping services. A good metal stamping provider can deliver premium parts reliably and cost-effectively.

The modern, collaborative economy leads lots of companies to partner up to produce the best possible products for retail sale. Many manufacturers rely on third parties to help them create precision components by providing metal stamping services. A good metal stamping provider can deliver premium parts reliably and cost-effectively.

Precision Metal Stamping: The Benefits

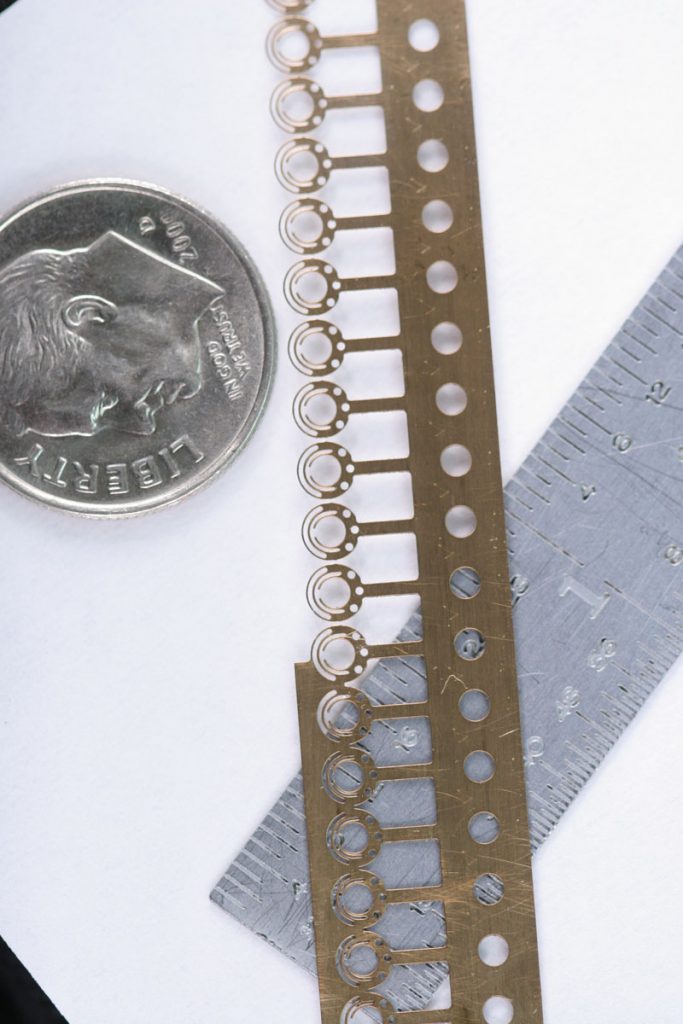

Metal stamping is a form of manufacturing that takes advantage of a high degree of automation. Parts or complete tools are created by cutting sheet metal precisely in die machinery. In the metal part manufacturing industry, stamping offers the following advantages:

* Very high precision; very tight tolerances.

* Extreme consistency of output and minimal potential worker error.

* Minimal labor cost and fast production

* Raw materials are used with great efficiency

Picking The Right Metal Stamping Provider

When you have a critical project to complete and you need the help of a reliable metal stamping provider, all of the following criteria are important in your choice of partner:

* Relevant Experience

You should consider both the overall amount of time the supplier has been operating and how much experience they have stamping components of the type you need. How much experience does the provider have with complex bends and intricate parts? Have they produced components in the past that meet your tolerance needs? It’s also worth asking how much the stamping company invests in keeping their technology and skills up-to-date.

* Die Designing/Building

As a general rule of thumb, an effective metal stamping partner should have experience with both the design and manufacture of stamping dies. This experience will lead to a high level of quality and consistency in the finished product and keep the stamping process efficient. Firms with extensive design and build experience also tend to be better at resolving unexpected problems in the stamping process.

* Equipment Used And Capabilities

The clearer an understanding you have of your specific needs (e.g. tooling, production processes, and press capabilities), the better you can assess a supplier’s capacity to meet those needs. At a very minimum, you should try to pick a firm that has already worked extensively with the specific metal or metals your projects call for.

* Process Control

Check the stamping company’s qualifications and skills in process control. These skills are vital to providing you with quality output according to your budget and schedule.

* Certification

Take a look at all certifications the supplier has to offer in terms of process and product quality.

* Die Maintenance

For long-term projects where you expect your supplier to provide large numbers of components, it becomes important to review the company’s programs for die maintenance. Longer die life will keep your components’ life cycle cost down.

* Delivery Performance

Learn everything you can about a stamping firm’s delivery track record. Do they quote reasonable time frames for delivery? Can they provide records verifying their ability to meet their quotes?

* Running Speed

It is in the interest of both you and the supplier to produce your components as quickly as possible. You don’t want quality to suffer, though! Does the supplier offer run speeds that will meet both your quality and budget goals?

* Project Details

Understand how a given supplier plans to coordinate your project with you. How will quality, schedule, and tolerance goals be met? What is the supplier’s spare tooling policy?

* Customer Service

You want a stamping provider that treats you like a proper partner, responding to questions, needs, and issues quickly.

Metal Stamping Uses

Virtually any industry with a high demand for precision makes use of metal stamping. Examples include:

* Medical manufacturing

* Aerospace

* Automotive

* Electronics

* Consumer Goods

* Agriculture

Satisfy Your Metal Stamping Needs With Reliable Expertise

Talk to the experts at Metric Tool and Stamping to put your project in the best hands. Our expertise with tool design and build is widely recognized in our industry. We have the precision, capacity, and experience you need to complete your stamping project quickly and affordably.