SPC Quality Control on Every Production Run

At MTSI, we're committed to providing our clients with the highest quality metal stampings in the industry. We utilize advanced SPC software (MeasurLink®) and advanced SPC quality control procedures to ensure consistently high quality on every production run.

We are able to track historical data for all of our parts up to 25 years and can tell you how each tool has performed. This tracking ensures that each of our stampings has the highest quality.

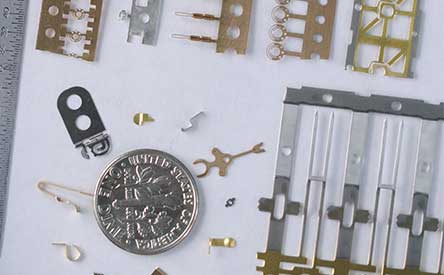

MTSI holds tolerances on precision micro stamping to within +/- .0002". We also incorporate Six Sigma Capabilities and are ISO 9001:2008 Certified.

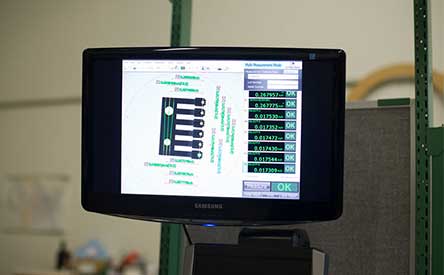

Computer-Aided SPC Quality Control

To ensure the highest quality parts consistently in every shipment, we use a variety of inspection methods and tools. Our Mitytoyo MeasurLink® SPC software system is a state-of-the-art, real-time inspection and data collection tool that provides immediate process control feedback, custom inspection routines, and fail-safe traceability.

Visual Inspections by Experienced Craftspeople

In addition to regular inspection routine and data collections, trained crafts people conduct visual inspections on a regular basis to detect possible surface blemishes and ensure the integrity of the cutting and forming components of your tool.

10 Million Parts – Guaranteed! Usually More!

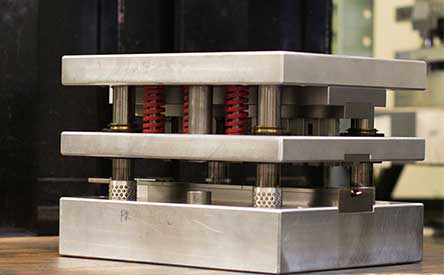

Our standard guarantee is 10 million parts without maintenance costs for tools we design, build, and run at our facility. However, many of our tools have gone way beyond 10 million parts. Several tools have produced 50-70 million parts without additional maintenance or component replacement costs! Durability and longevity is built into every tool we make.

ISO Certification

Rose Creek Anglers, Inc.

When we transferred production of our programming cables from an outside vendor to our in-house production, Metric Tool provided the most critical part of the solution. Their staff worked with me in the contact design process which greatly reduced our manufacturing costs. Metric Tool places a higher value in their relationships with companies than with monetary expectations. Since the time of the programming cable project, they have provided a great deal of die design advice.

Resistance Technology

“Metric Tool & Stamping has been supplying us with precision micro-stampings for our electronic control assembly for more than twelve years. Their stampings are always very precise…especially in the critical areas of the part. For example, they produce a complex insert stamping on one of our switch lead frames that they consistently hold to within .0001. Metric is one of the best tool houses in the business.”

Omnetics Connector Corp.

“[MTSI] has been a principal supplier to Omnetics for over ten years. Metric has tooled and produced a variety of close-tolerance stamped electrical contacts critical to Omnetic's needs. They've demonstrated their skill in doing the tough parts with a visible pride in workmanship. I value our good working relationship.”

Rollerblade, Inc.

Metric supplies us with several stamped parts for our in-line skates. As the world leader of in-line skates, we require quick response on large quantities. [MTSI] has always delivered on time, and [they are] extremely responsive to our needs. They always call first when questions come up. We definitely appreciate working with a solid company like Metric.”